.webp)

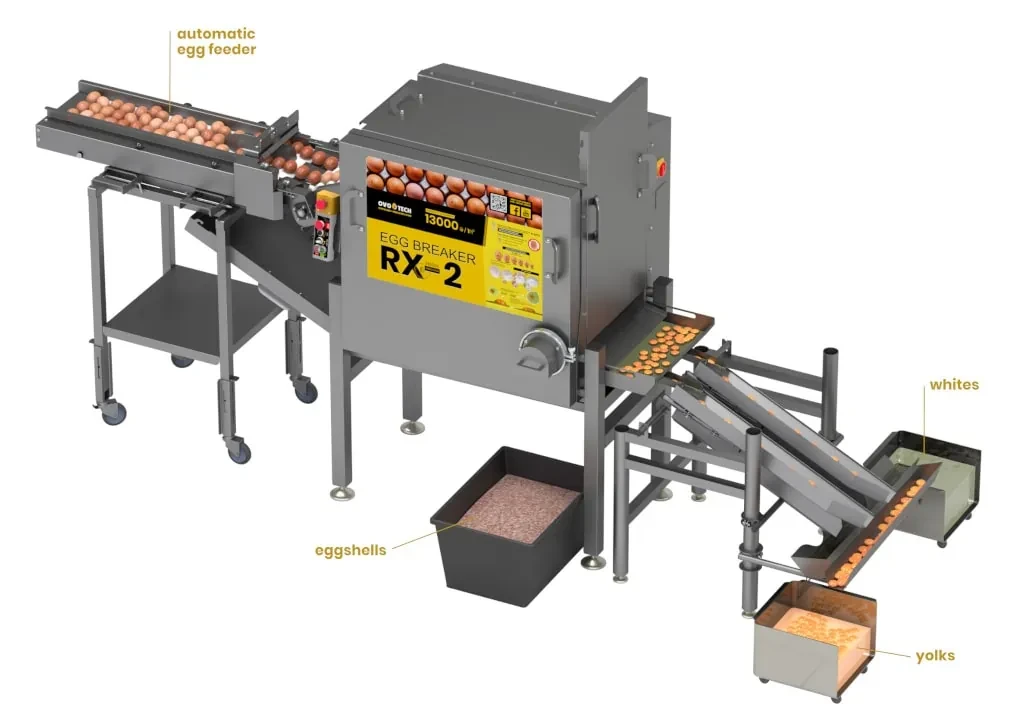

RX-2 Egg Cracker (Self-Cleaning) 13000 Eggs/Hour

Shipped by Tervinox

Shipped by Tervinox

Shipped by Tervinox

Shipped by Tervinox

.webp)

Great warranty

2 year warranty with excellent service

Reliable delivery

Free delivery for purchases of 500 SAR or more

Easy of payment

You will find easy in payment processes with us

.webp)

Great warranty

2 year warranty with excellent service

Reliable delivery

Free delivery for purchases of 500 SAR or more

Easy of payment

You will find easy in payment processes with us

Description

The RX-2 egg breaking machine uses a self-adjusting belt feeder with a specially designed pulley system to transport eggs to the breaking section. The machine's high performance is achieved thanks to the use of best-in-class innovative breaking mechanisms. The machine breaks eggshells using specially designed knives, mimicking the action of human hands. This hygienic method of breaking eggs is an innovation from OVO-TECH. The eggs then pass through a high-quality control tray. They then slide down a separator ramp where the yolk is separated from the white. The remaining eggshells after breaking are reduced by our comprehensive eggshell crushing machine, reducing their volume by 95%. After completion of the process, the machine can be cleaned using a built-in CIP system. Machine made of EN 1.4301 (AISI 304) stainless steel

Capacity: 13,000 eggs/hour

230V 3/N/PE 50/60Hz

Dimensions: 4672 x 1090 x 1795 mm [184 x 43 x 71 in]

Small working area: 5600 x 2090 mm [221 x 83 in]

Weight: 415 kg [915 lb]

Additional Information

Water connection and drainage are required to ensure efficient operation of the Clean-in-Place (CIP) system. If the egg quality is poor and the yolk is to be separated from the white, the eggs must be cooled to below 14°C (57°F) before crushing. We recommend a simple egg quality test. Integrated with the UZS system. All parts of our machines that come into contact with eggs are made of EN 1.4301 (AISI 304) stainless steel.